Description

Sheet metal stainless steel aluminum guillotine shearing machine with automatic air rear support

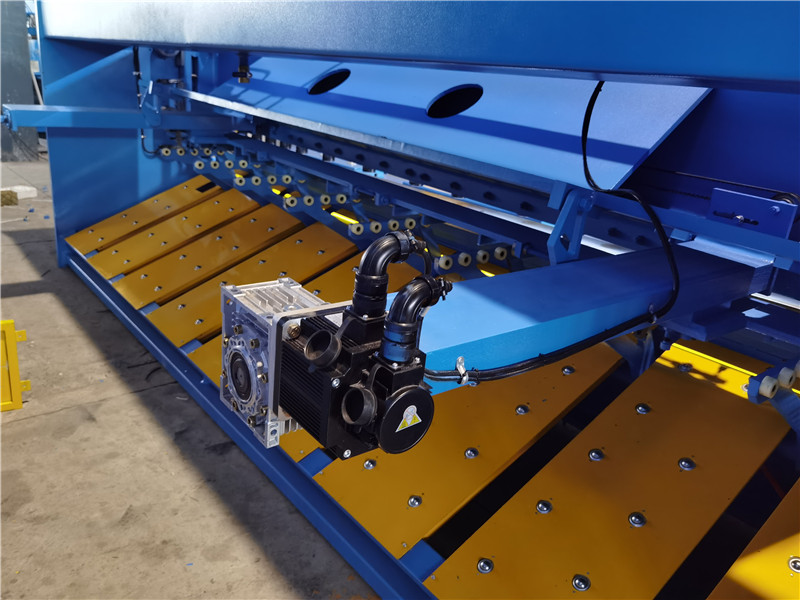

The utility model relates to a simple pneumatic rear support device for a shearing machine, in particular, it is specially used for the shearing machine to cut wide and thin plates, and supports the plate material before cutting, so as to help it locate when it is positioned with a baffle plate Accurate, simple pneumatic support device that slides out the sheet after cutting, and belongs to the metal sheet metal processing industry.

Sheet metal stainless steel aluminum guillotine shearing machine with automatic air rear support Background technique:

In the prior art, there are many structures for the pneumatic rear support of the shearing machine, but most of them are complicated in structure, have many parts, and are troublesome to process, install and debug, so the manufacturing cost is greatly increased.

Technical implementation elements:

The purpose of the utility model is to overcome the above-mentioned deficiencies, thereby providing a simple and easy-to-make pneumatic rear support device for a shearing machine, which can easily achieve the functions of holding the sheet before cutting, assisting positioning, and sliding out the sheet after cutting, It can achieve the effect of supporting and unloading.

According to the technical solution provided by the utility model, the simple pneumatic rear support device for the shearing machine is characterized in that it includes a discharge plate and a pneumatic support frame, and the discharge plate and the pneumatic support frame are installed on the shears. On the inner side of the trigger wall panel, the discharge plate is installed above the pneumatic support frame, and the support rod on the pneumatic support frame extends out of the bending part before shearing by the shearing machine; the discharge plate is composed of angle steel, support rods and several It is composed of bending parts; the angle steel is fixed on the machine table, the two ends of the support rod are respectively fixed on the inner side, rear and bottom of the left and right wall panels, and the two ends of several bending parts are respectively connected with the angle steel and the support rod. Below the plate, it consists of two pallets with the same parts installed symmetrically.

As a further improvement of the present utility model, each support frame is composed of a plurality of support rods, a rotating shaft, a cylinder with a valve, a block, a rocker arm, an expansion sleeve, a tension cover, a bearing with a seat, a backing plate and a support rod; the The supporting rod can be installed on the rotating shaft at any angle through the expanding sleeve and the tightening cover. The rotating shaft is fixed on the vertical plate below the worktable of the shearing machine with a seat bearing. One end of the rocker arm is connected with the rotating shaft by a key, and the other end is connected with the cylinder with valve. The y-shaped connecting rods with pins on the upper part are connected, the stopper is fixed on the vertical plate of the workbench above the rocker arm, and the ear seat at one end of the cylinder with valve is welded and connected to the vertical plate of the workbench through the backing plate.

As a further improvement of the present invention, a gap of 45-60 mm is left between the several bending parts.

As a further improvement of the present utility model, the material support frame further includes a plurality of nylon rollers and pins, and a plurality of nylon rollers and pins are mounted on the support rod.

As a further improvement of the utility model, the height of the nylon roller is flush with the lower blade of the shearing machine, and the nylon roller supports the sheared sheet entering from the direction of the lower blade to prevent the sheared sheet from sagging due to its own weight.

Sheet metal stainless steel aluminum guillotine shearing machine with automatic air rear support .

Features of this machine

1.The second generation of shear.

2.Welded steel plate construction, heating to eliminate stress,with high strength and good rigidity.

3.Advanced integrated hydraulic system with and excellent reliabitity quality.

4.Rapidly,accurately and conveniently adjusting the blade clearance by motor

5.The adjustable rake angle can minimize plate deformation.

6.As the cutting beam has been designed in inner-inclined structure,it is easy for plates to fall down and the accuracy of products can be also guaranteed.

7.Shearing in sections,shadow-line cutting.

8.Counter for the motorized back gauge.

9.Back support device (optional).