What is the future development trend of CNC press brake bending machine system?

Automatic CNC press brake bending machine price classification

When it comes to purchasing a fully automatic CNC press brake bending machine, everyone first considers our own budget. This is the main one. Then filter the CNC press brake bending machine we need according to our own budget and required functions.

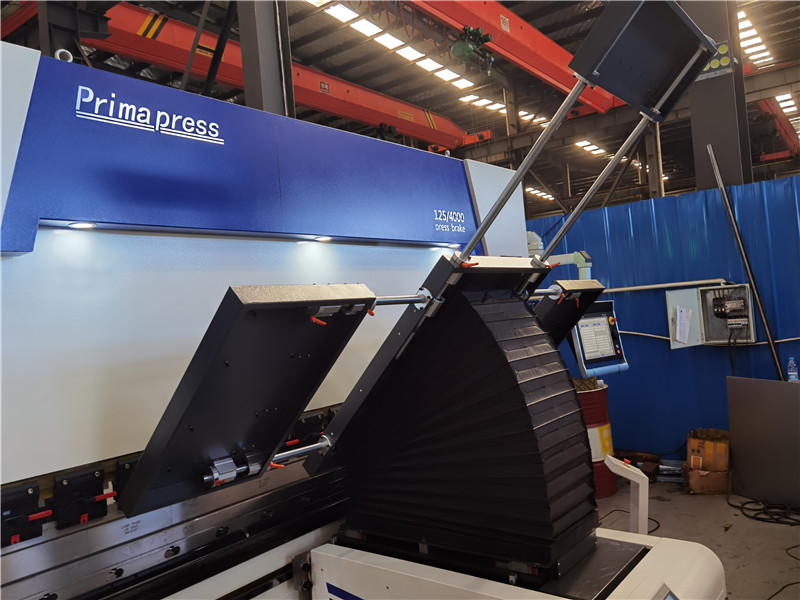

The automatic CNC press brake bending machine mainly refers to the sheet metal bending machine, which is used for the bending and forming operation of the metal sheet. The bending machine can be divided into different types according to the working characteristics and methods. The CNC press brake bending machine has fully automatic operation, which improves the bending quality, labor efficiency, reduces labor costs, and greatly shortens the production cycle of products. The hydraulic bending machine has hydraulic upper transmission, stable and reliable, mechanical shifting, torsion shaft synchronization, high precision, electric adjustment of rear gauge distance and upper slider stroke, and digital display.

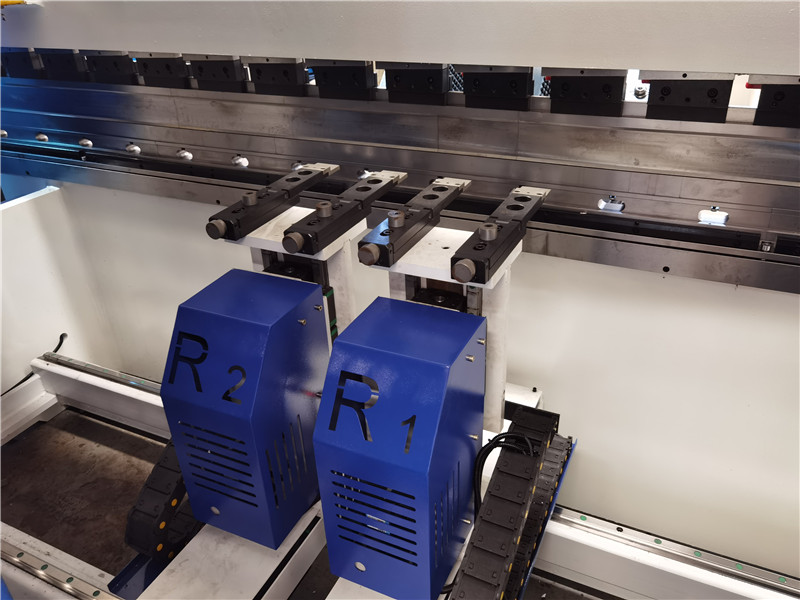

The features of the automatic CNC press brake bending machine are: it adopts all steel plate welding; adopts C-shaped structure, and the whole machine is processed; adopts electro-hydraulic synchronous structure, so that the positioning accuracy of the oil cylinder is high, the bending accuracy is within 0.5 degrees, and it has a super strong Anti-eccentric load capacity. The lift height of the slider can be set on the numerical control system, the back gauge automatically retreats, and the angle is directly input. According to user needs, there are various options for the back gauge, such as 3+1 axis, 4+1 axis, 6+1 axis.

The bending machine is a machine that can bend thin plates. Its structure mainly includes a bracket, a worktable and a clamping plate. The worktable is placed on the bracket. The worktable is composed of a base and a pressure plate. The base is composed of a seat shell, a coil and a cover plate, the coil is placed in a depression of the seat shell, and the top of the depression is covered with a cover plate. During use, the coil is energized by the wire, and after the electricity is energized, the pressure plate is gravitationalized, so as to complete the clamping of the thin plate between the pressure plate and the base. Because of the selection of electromagnetic force clamping, the pressing plate can be made into a variety of workpiece requirements, and the workpiece with side walls can be processed, and the operation is also very simple. From the current point of view, the development trend of CNC press brake bending machine system is mainly reflected in three aspects: function, function and system structure. The specific expression is:

- High precision, high speed and high efficiency

Power and quality are the key functional indicators of advanced production technology and the main body of advanced production technology. If the use of high-speed CPU chips, RISC chips, multi-CPU control systems, high-resolution detection components, communication digital servo systems, supporting electric spindles, linear motors and other technologies can greatly improve power, improve product quality and level, shorten production cycle and Improve market competitiveness. In the next few years, ultra-fine CNC press brake bending machine punches are developing towards refinement, high speed, intelligence and nanotechnology, and a new generation of CNC press brake bending machine tools is assembled.

- Flexibility

The CNC press brake bending machine system adopts a new generation of modular design, with wider functional coverage and stronger reliability, which can meet the needs of different users. The same group control system can actively adjust the information flow dynamically according to different production processes, and give full play to the function of the group control system.

- Multi-axis

Multi-axis linkage processing, after the parts are clamped on a CNC press brake bending machine for one time, operations such as automatic tool change, rotating spindle head, rotating table, etc. can be performed to complete multi-process and multi-surface composite processing, not only high finish, And the power is also greatly improved.

- Open software and hardware

Users can carry out the secondary development of the CNC press brake bending machine system software according to their own needs, and the user’s application scope is no longer restricted by the manufacturer.

- Intelligent

In the field of CNC press brake bending machine technology, the research and application of real-time intelligent control are being carried out along: adaptive control, fuzzy control, neural network control, expert control, learning control, feedforward control, etc. For example, the programming expert system fault diagnosis expert system, when the system fails, the diagnosis and maintenance are completed intelligently..