Working principle and maintenance of four-column hydraulic deep drawing press machine

The four-column hydraulic machine is the hydraulic oil of the oil pump to the integrated cartridge valve block, which passes through the lower chamber of the hydraulic cylinder

of various distributed check valves and safety valves or oil under the action of high deep drawing press machineure, and the cylinder moves. Hydraulic oil is used to transfer

deep drawing press machineure equipment. The delivery deep drawing press machineure of hydraulic fluid in a closed container follows Pascal’s law. The hydraulic transmission

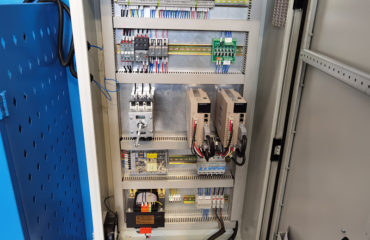

system of a four-column hydraulic deep drawing press machine includes a power mechanism, a control mechanism, a transmission device, an auxiliary mechanism and a working medium.

Use oil pump as power, deep drawing press machine power mechanism is usually oil pump for product type. In order to meet the requirements of the movement speed of the actuator, the hydraulic machine chooses one pump or more oil pumps mainly for energy saving and increasing the deep drawing press machineing speed. To

The oil pump supplies oil to the small piston. The small piston drives the large piston down (upper deep drawing press machine), the large piston forms a vacuum, the filling valve opens,

and the oil in the high oil tank flows into the large piston by its own weight to ensure that the large cavity is always filled with oil. After contacting the workpiece, the deep drawing press machineure rises and the system reversing valve acts. The oil pump supplies oil to the big piston, because the big piston is full of hydraulic oil, and the hydraulic machine can

quickly generate huge deep drawing press machineure. To

If there is only a large piston, a large oil pump must be used in order to ensure the deep drawing press machineing speed of the oil cylinder. A large flow and high deep

drawing press machineure oil pump requires a large motor, which is a waste.

Maintenance of four-column hydraulic deep drawing press machine

Common failures and maintenance methods of four-column hydraulic deep drawing press machinees: often in the hydraulic transmission system, there are some relatively precise parts.

Although people feel labor-saving and convenient for mechanical hydraulic transmission, they also feel that it is easy to damage. The main reason is that it is not very clear about its working principle and structural characteristics, and therefore does not know much about its preventive maintenance methods. There are three basic “pathogenic” factors in hydraulic systems:

pollution, overheating and air intake. These three unfavorable factors have a close internal relationship. Any one of them will cause another one or more problems. Practice has proved

that 75% of the “diseases” causes of the four-column hydraulic system are caused by these three. 1. The working fluid is deteriorated by entering the dirt. 2. Overheating. 3. Into the air.

Solution: The cleaning and assembly of some major precision parts in the system should be carried out in a very clean room with a clean floor and airtightness. For doors and windows, the temperature is best kept at about 200C.

Other common maintenance of four-column hydraulic deep drawing press machine:

1. L-HL32/GB1118-89 hydraulic oil, N46/GB3141 can be used when the degree of universal N32/GB3141 is higher than 30 degrees when it is lower than 20 degrees.

2. The oil industry is allowed to enter the fuel tank only after strict filtration.

3. The working fluid is replaced once a year, and the first replacement time should not exceed three months;

4. The sliding block should be lubricated frequently, and the exposed surface of the column should be kept clean frequently, and lubricating oil should be sprayed before each work.

5. Under the nominal deep drawing press machineure of 500T, the maximum allowable eccentricity of the concentrated load is 40mm. Excessive eccentricity may cause strain

on the column or other undesirable phenomena.

6. Calibrate and check the deep drawing press machineure gauge every six months;

7. If the machine is out of service for a long time, the surface of each processing plant should be scrubbed clean and coated with anti-rust oil.

How is the four-column hydraulic deep drawing press machine maintained?

Pay great attention to the storage and transfer of working oil. Oil drums should be specially marked and covered up. In winter, be careful not to mix the oil into the barrel due to the

air condensing into moisture, and do not drop the rusty rust on the barrel skin into the barrel. A number of preventive measures taken for the engine and other mechanical systems

in winter, such as covering up anti-freezing, heating and insulating, and changing to low-viscosity working oil, are all applicable to hydraulic systems. …

In winter and under bad working conditions, the four-column hydraulic deep drawing press machine system should be inspected and maintained frequently, and the working fluid should be changed frequently. …

Four-column hydraulic deep drawing press machine Common failures and maintenance methods of hydraulic deep drawing press machinees: often in the hydraulic transmission system,

there are some relatively precise parts. Although people feel labor-saving and convenient for mechanical hydraulic transmission, they also feel that it is easy to damage. The main reason

is that it is not very clear about its working principle and structural characteristics, and therefore does not know much about its preventive maintenance methods. There are three basic “pathogenic” factors in hydraulic systems: pollution, overheating and air intake. These three unfavorable factors have a close internal relationship. Any one of them will cause another

one or more problems.

It has been proved by practice that 75% of the “diseases” causes of the hydraulic system are caused by these three factors:

- The working fluid has deteriorated due to contamination

- Overheating

- Air entry solution: The cleaning and assembly of some main precision parts in the system should be carried out in a very clean room. The room should have a clean floor and

- closed doors and windows. The temperature should preferably be kept at about 200C.

ess

ess