Safety Operating Regulations for Sheet Metal cnc turret Punch Machinery

Sheet metal cnc turret punch machinery comprehensive report 1. Sheet metal cnc turret punch mechanics must learn, master the structure and performance of

sheet metal cnc turret punch machinery, and be familiar with the operating procedures and obtain operating permits before they can operate independently.

The sheet metal cnc turret punching machine should be used by a dedicated person and is strictly prohibited from being operated by other personnel.

2. The labor protection equipment should be worn correctly when going to work in the workshop.

2. Correctly use the safety protection and control device of the metal plate cnc turret punching machine, and shall not be dismantled arbitrarily.

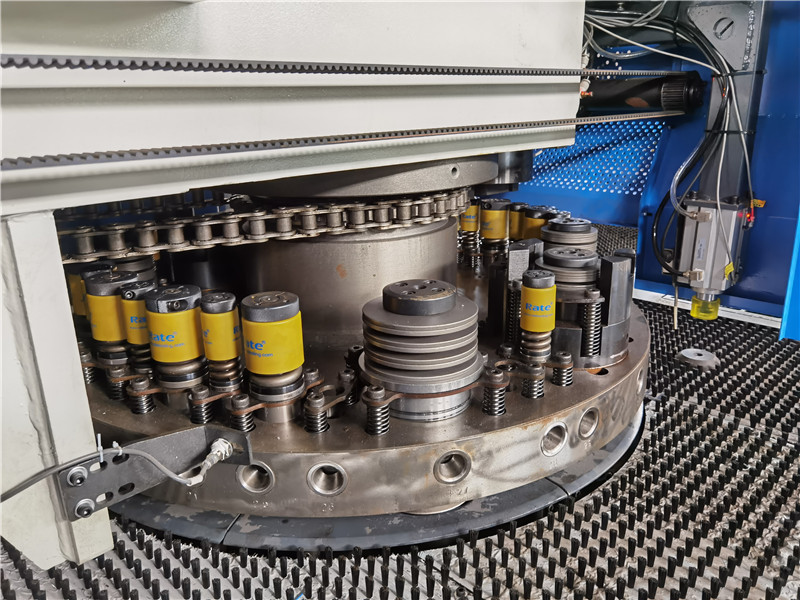

3. Remove objects that hinder operation on the work site before work. , Check whether the transmission, connection, lubrication and protective safety devices of the

sheet metal cnc turret punching machine are normal. The screws of the mold must be firm and must not be moved. Check whether the mechanical moving parts of the

sheet metal cnc turret punch press (such as guide rails, bearings, etc.) are filled with lubricating oil. The sheet metal cnc turret punching machine should run idling for

1-3 minutes before working. Check whether the flywheel is running smoothly. Check the flexibility of the clutch, brake and other control devices, and use it after confirming

that it is normal. It should not run with illness.

- When the equipment is running, it is strictly forbidden to reach into the sliding block area. When adjusting or repairing the machine tool, you must turn off the power

- and hang a “no operation” warning sign. When you need to jog or start, notify every worker. Otherwise, it is not allowed to start.

4. The punching force must be verified, and overload operation is strictly prohibited.

5. Turn off the power first, and wait for the metal plate cnc turret punching machine to stop the mechanical movement before installing and adjusting the mold.

If the knife edge is worn before the burr exceeds the standard, the knife edge should be sharpened in time.

6. The mold must be tight and firm, the upper and lower molds are aligned to ensure the correct position, after installation and adjustment, the metal plate

cnc turret punching machine mechanical test punch (empty car) is moved by hand to ensure that the mold is in good condition.

7. The mold installation must be firm and reliable. When adjusting the height, use manual or moving methods, and proceed step by step. Before confirming the adjustment,

it is forbidden to connect cars.

8. Before starting the sheet metal cnc turret punch machine, other people leave the sheet metal cnc turret punch machine working area and remove the debris on the

workbench before turning on the power supply.

- After the sheet metal cnc turretpunch machine is started, one person will carry out the feeding and punching operations. Others are not allowed to press the electric button

- or step on the foot switch board, and cannot put their hands in the sheet metal cnc turretpunch machine working area or use their hands. Touch the moving part of the sheet metal cnc turret punch machinery. During a single punching, the feet are not allowed to be often placed on the pedals. After each punching, leave the pedals immediately to prevent accidents.

10. Generally, it is forbidden for two or more people to operate the sheet metal cnc turret punching machine at the same time. If necessary, someone must be instructed

and responsible for the operation of the pedal device. When two or more people work together, the person responsible for moving (stepping on) the gate must pay attention to

the actions of the feeder. It is strictly forbidden to pick up the parts while moving (step on) the gate.

- When the sheet metal cnc turretpunch machine is taken out or is running and punching, the operator must stand properly, his hands and head should be kept a certain

- distance from the sheet metal cnc turretpunch machine, and always pay attention to the movement of the punch. Concentration of thoughts, it is strictly forbidden to talk

- while doing, and cooperate with each other to ensure safe operation.

12. When punching short and small workpieces, special tools should be used, and it is not allowed to directly feed or pick up parts by hand. When punching or

long-body parts, safety racks should be set or other safety measures should be taken to avoid digging injuries.

13. It is strictly forbidden to carry out the feeding and unloading of the mold in any part of the body during work. Special tools should be provided.

14. It is forbidden to press the interlayer feed material, and the second feed material must be removed after the first punch or the remaining material is removed.

15. The mold installation must be checked regularly, and if there is looseness or slippage, it should be adjusted in time.

16. It is found that the sheet metal cnc turret punch machine has abnormal sound and mechanism failure, and the power switch should be turned off immediately for inspection.

17. When disassembling the mold, it must be carried out in the mold-clamped state.

18. Take good care of stamping equipment, dies, tools, measuring tools and instruments. Stop the machine in time when the work is finished, and cut off the power,

the mold and the metal plate cnc turret punch should be mechanically wiped clean and ready.

19. When the work is over, wipe the machine. According to the production batch, a reasonable cutting method is adopted, and the large materials are discharged first,

and the small materials are discharged later, so as to maximize the utilization rate of materials.