Description

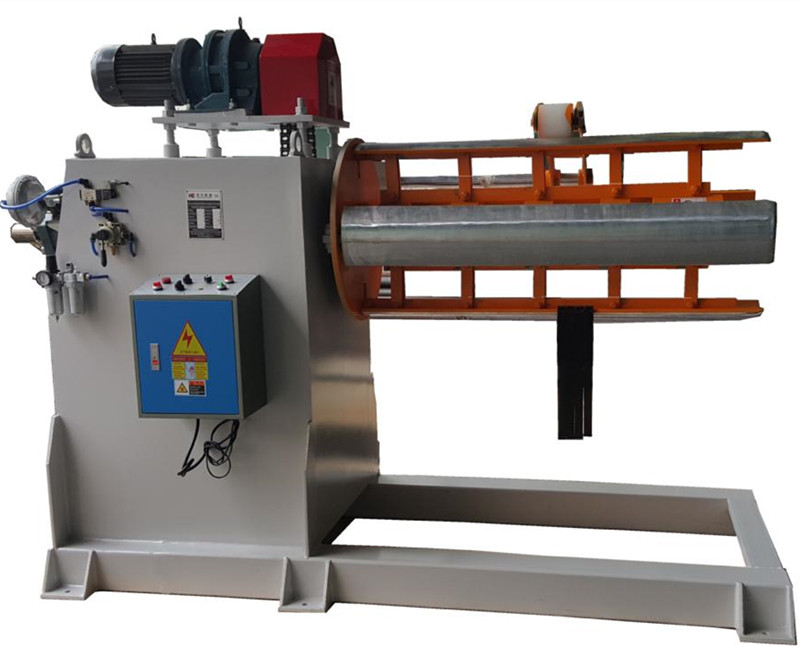

metal Coil uncoiler, 2in1 Uncoiler and straigter , coils decoiler machines

About the 2IN1:

- Uncoiler and straightener two in one style improve factory usable space.

2. Straightening adopts the balance adjusting equipment and suitable for processing higher precision products.

3. Roller adopts the solid bearing steel and hard chrome plating treatment.

Features:

1. Equipped with precision adjusting micro components, Japan magnetic contractor and electronic components, minimum breakdown and long operating life.

2. Integrated with straightener and uncoiler into one machine, save volume, suitable for board processing. Automatically adjust feeding time according to output speed.

3. Hard-chrome plated rollers adopts the solid bearing steel, low wear and high precision

4. Controlled by modern transducer, a various speed control is used for normal and high speed operation, keep pace with straightening, stable feeding.

- Integrated with Uncoiler and straightener. Save volume, suitable for board processing. Automatically adjust feeding time according to output speed.

6. All rolls are made of bearing steel, have all been quenched, hard-chrome plated and grinded with mim HRC60 degree.

7. Use Japanese electromagnetic contact and electric parts, long service life .

8. A step-less variable speed control is used normal and high speed operation, control by modern frequency converters, keep pace with straightening, stable feeding.

9. Leveler inclines appropriately to reduce feeding loop distance.

10. Constructed with highly rigid structure and designed with a powerful motorized feeder

Specification:

| Model | PR-150 | PR-200 | PR-300 | PR-400 | PR-500 | ||||

| Max. material width | 150mm | 200mm | 300mm | 400nn | 500mm | ||||

| Material thickness | 0.4-1.5mm | ||||||||

| Material weight | 500kg | 800kg | 1000kg | 1500kg | 2000kg | ||||

| Coil inner diameter | 450-530mm | ||||||||

| Coil outer diameter | 1200mm | ||||||||

| Straightening motor | 1/2(HP) | 1 (HP) | 2 (HP) | 2 (HP) | 3(HP) | ||||

| Uncoiler motor | 1 (HP) | 1 (HP) | 2 (HP) | 2(HP) | 3 (HP) | ||||

| Straightening roller | Diameter 20*9/10(up/down)full drive | ||||||||

| Straightening adjusting | 4 point adjusting | ||||||||

| Straightening speed | 0-15m/min | ||||||||

| Expansion style | manual | ||||||||

| Induction | Induction table style | ||||||||

if bigger one, we can also make, just tell me the thickness and width of coils.

NC Feeder Components list:

| Electrics | SCHNEIDER | For electric safety |

| Servo motor | YASKAWA from Japan | For long time using |

| PLC controller | Delta from Taiwan | To control the movement and speed |

| Man-machine interface | WEINVIEW from Taiwan | For convenient operation |

#punching machine #hole punching machine #cnc punching machine

#metal punching machine #hydraulic punching machine